- info@cfiholding.com

- SINGAPORE

Conditioning

The conditioning represent the drying and cooling of a solid product without damaging it. In most of the cases, air is used as drying or cooling medium.

DRYER DRUM

Dryer drum is possibly the most common way of drying of crystals, prills and granules. It is used to condition the crystals, prills or granules by bringing it into contact with hot air. The drum is a rotating cylindrical equipment in which the material moves through with help of lifters and progress to the discharge end under the influence of gravity.

Products by dryer drum

References:

COOLER DRUM

Cooler drum is possibly the most common way of cooling of crystals, prills and granules. It is used to condition the crystals, prills or granules by bringing it into contact with conditioned air. The drum is a rotating cylindrical equipment in which the material moves through with help of lifters and progress to the discharge end under the influence of gravity.

Products by cooler drum

References:

FLUIDIZED BED COOLER (FBC)

FBC, which uses the fluidization principle for cooling solid particles, is a very effective way of cooling of prills and granules. Solid particles can be quickly cooled down in FBC as maximum surface of the material is exposed to colder environment.

Products by FBC

References:

DRYER + FBC

It is a combination of drum dryer and FBC. This system allows hot air from fluidized bed cooler to be recirculated to dryer. The advantages of this arrangement is that it improve the energy efficiency of the system and less air released through scrubber and stack.

Products by dryer + FBC

Projects:

SCREEN AND CRUSHER

Screen

The aim of a screening system is to separate the marketable granules or prills (good size) from the fines and oversize. Screening machines are generally equipped with two decks. The mesh size of each deck depends on the required particle size of the final product. The product enters from the top of the screen and crosses the decks on a slight slope. To avoid clogging, screening machines are equipped with vibration devices.

- In case of prilling process, the fine and oversize (generally less than 10% of the inlet) are remelted after the evaporation step.

- In case of granulation process, the oversize (generally less than 10% of the inlet) are crushed and recycled back with the fines (generally between 50 and 70% of the inlet) into the granulator and used as seeds.

The decks of the screening system can be either superposed or consecutive.

- Superposed decks screens are more compact but the cleaning of the lower deck is very difficult. This technology is used only for non-sticky products (such as AN prills).

- Consecutive decks screens take more space but each deck can be easily cleaned. This technology is used for sticky products (such as NPK). For products with a very high sticky tendency (such as urea-based NPK), the top of screening machine can be open very easily for a mechanical cleaning (done during operation, 2 to 3 time per shift).

Crusher

The crushing is a mechanical operation used for reducing the size of particles.

Crushers are used:

- Either on raw materials, when they come in too large particles for dissolution or granulation

- Or on oversize from the screens, before recycling it as seeds to the granulator.

Crushers must be adjustable for ensuring the best operation of the granulator.

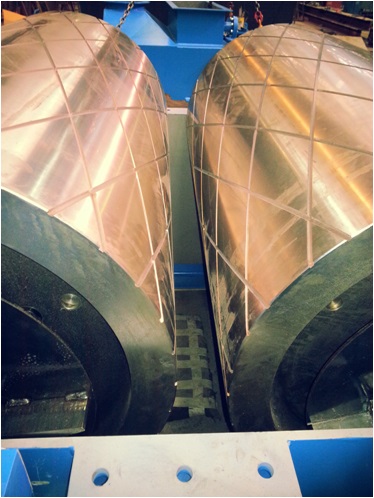

Several crushing technologies exist, such as roller crusher or pendular.

Products by screen and crusher

References

COATING DRUM

Coating drum is used for uniform coating of prills and granules with an anti-caking agent. The drum is a rotating cylindrical equipment in which the material moves through the drum and the anti-caking agent is sprayed on the material.