- info@cfiholding.com

- SINGAPORE

Crystallization

Crystallization is the best way to obtain purified products. The kind of crystallizer is often linked to the required crystal size.

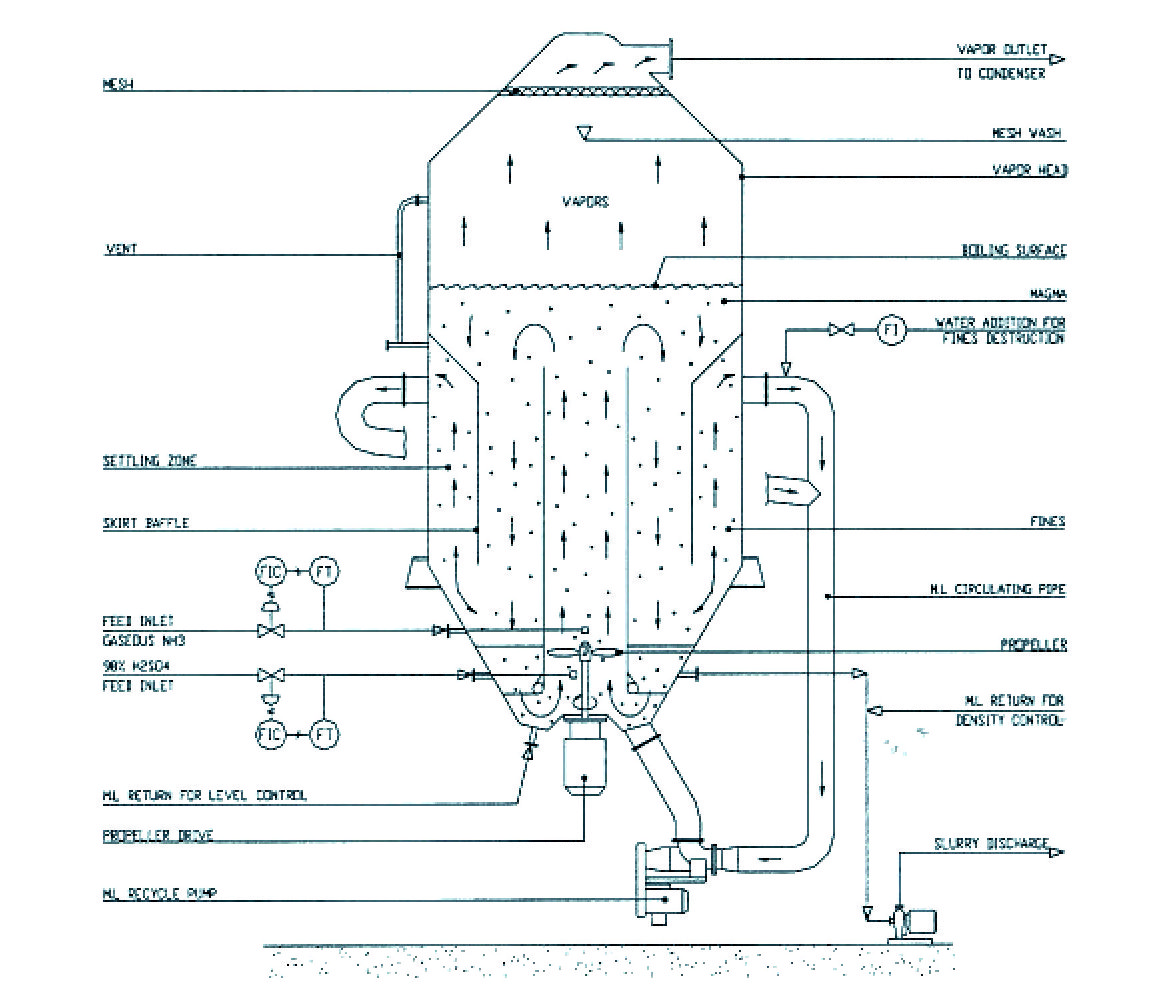

DRAFT TUBE BAFFLES (DTB) CRYSTALLIZER

DTB crystallizers provide superior control over crystal size and characteristics. For superior control over particle size when excessive fine crystals are present, the DTB crystallizer has been proven highly effective.

Products by DTB crystallizer

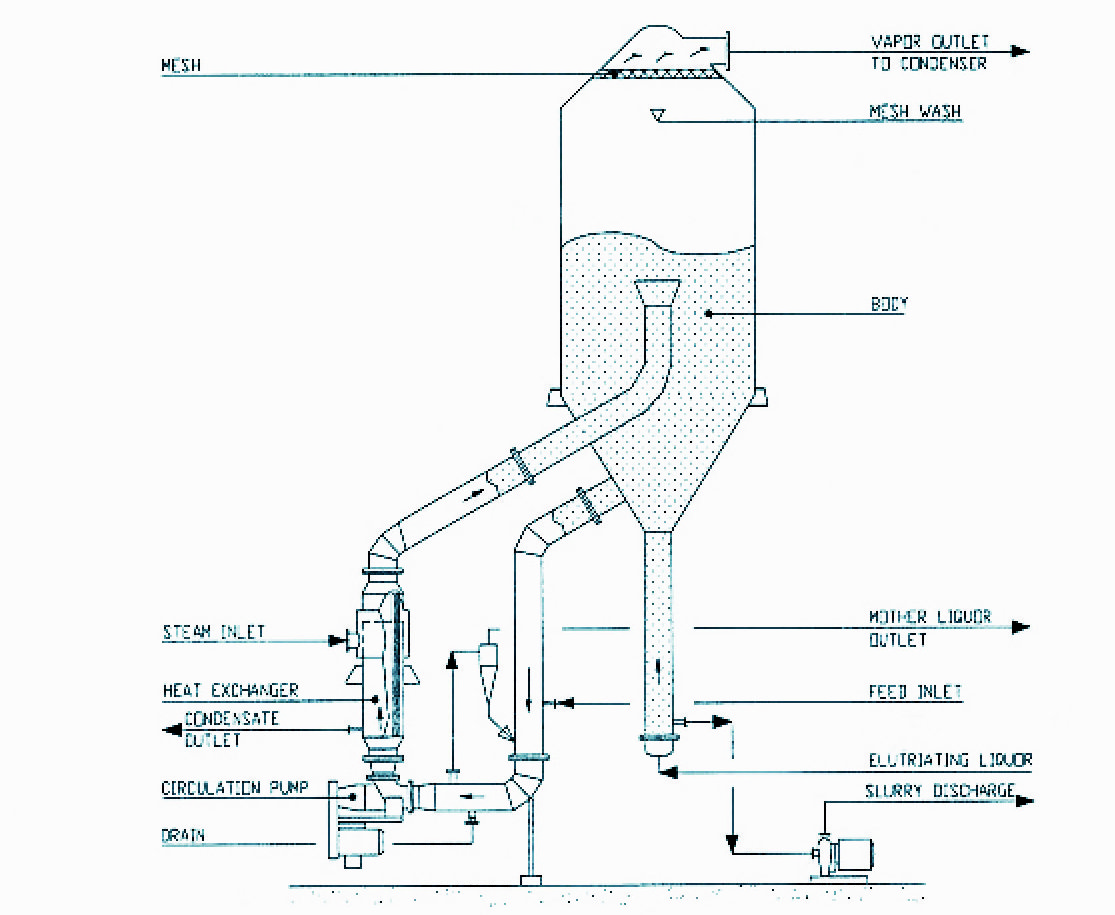

FORCED CIRCULATION (FC) CRYSTALLIZER

The FC crystallizer is used for applications where high rates of evaporation are required. It is also used for scaling compounds, inverted solubility solutions and solution is of relatively high viscosity.

Products by FC crystallizer

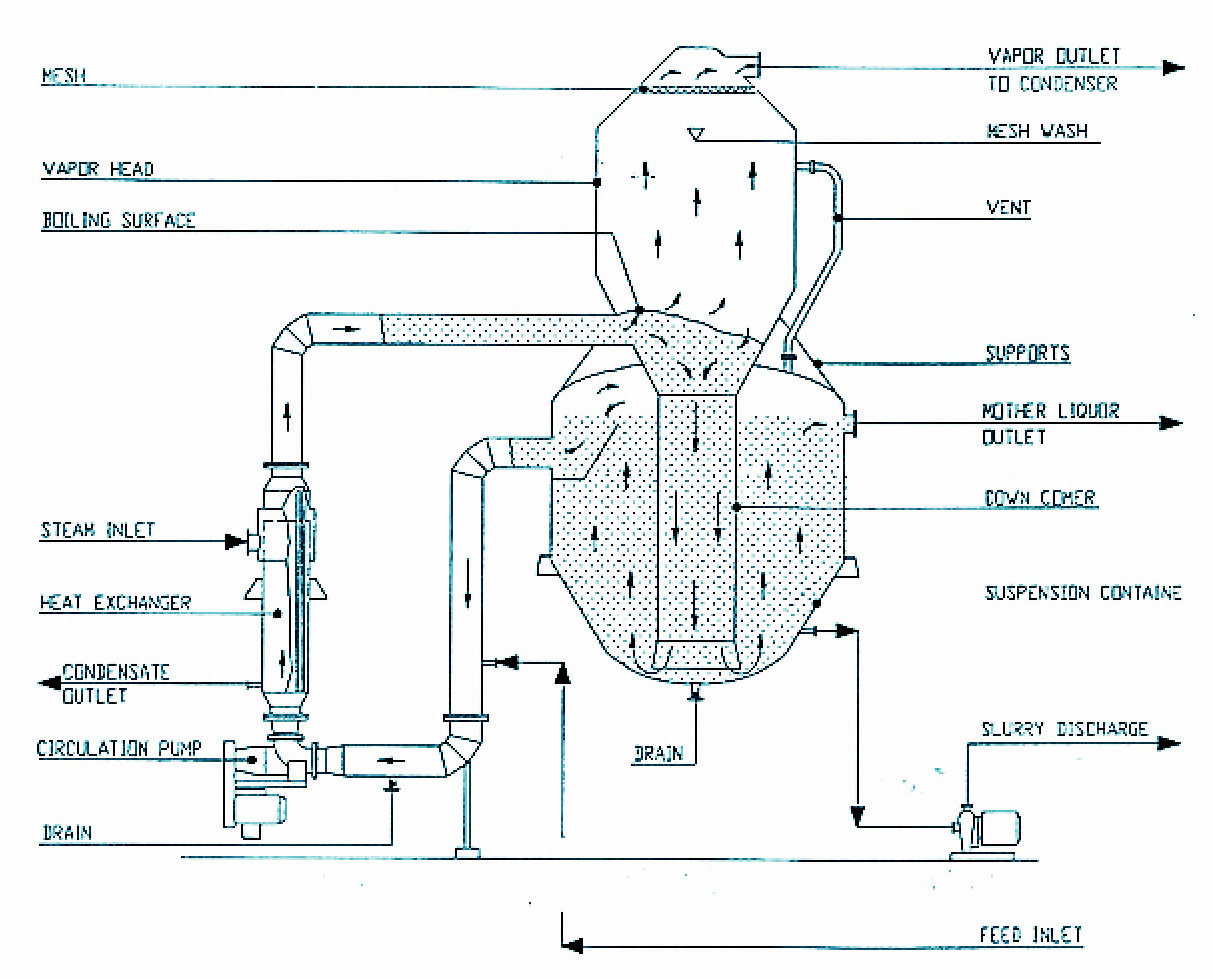

OSLO CRYSTALLIZER

The Oslo crystallizer also known as growth crystallizer is used for the production of large, coarse crystals.

The Oslo crystallizer work on de-supersaturation of the mother liquor through contact with the largest crystals present in the crystallization chamber. The smaller crystals are kept in suspension by a stirring device enabling the production of large crystals.

Products by Oslo crystallizer

DRY CRYSTALLIZATION

The “dry crystallization” consist of a pipe reactor installed at the top of a prilling tower. Inside the pipe reactor, ammonia reacts with an acid to form crystals. This technology provides very small crystals.