- info@cfiholding.com

- SINGAPORE

Granulation

Granulation represents all the techniques used for the formation of granules. It could be by accretion or agglomeration. Granules have generally a high hardness.

STEAM GRANULATOR

Steam granulator is a granulator where steam is used as a granulating agent. The steam is distributed uniformly and diffused into the rolling bed, producing spherical granules with larger surface area.

Products by steam granulator

References:

CHEMICAL GRANULATOR

Chemical granulator is a granulator where the reaction between the reactants takes place within the granulator, either in a pipe reactor installed in the granulator or in the bed of granulator. The slurry produced due to the reaction works as the granulating agent.

Products by chemical granulator

Without pipe reactor

With pipe reactor

References:

PAN GRANULATOR

Pan granulator is a specialized equipment where granulation is done through agitation agglomeration where steam is used as binder.

Products by pan granulator

References:

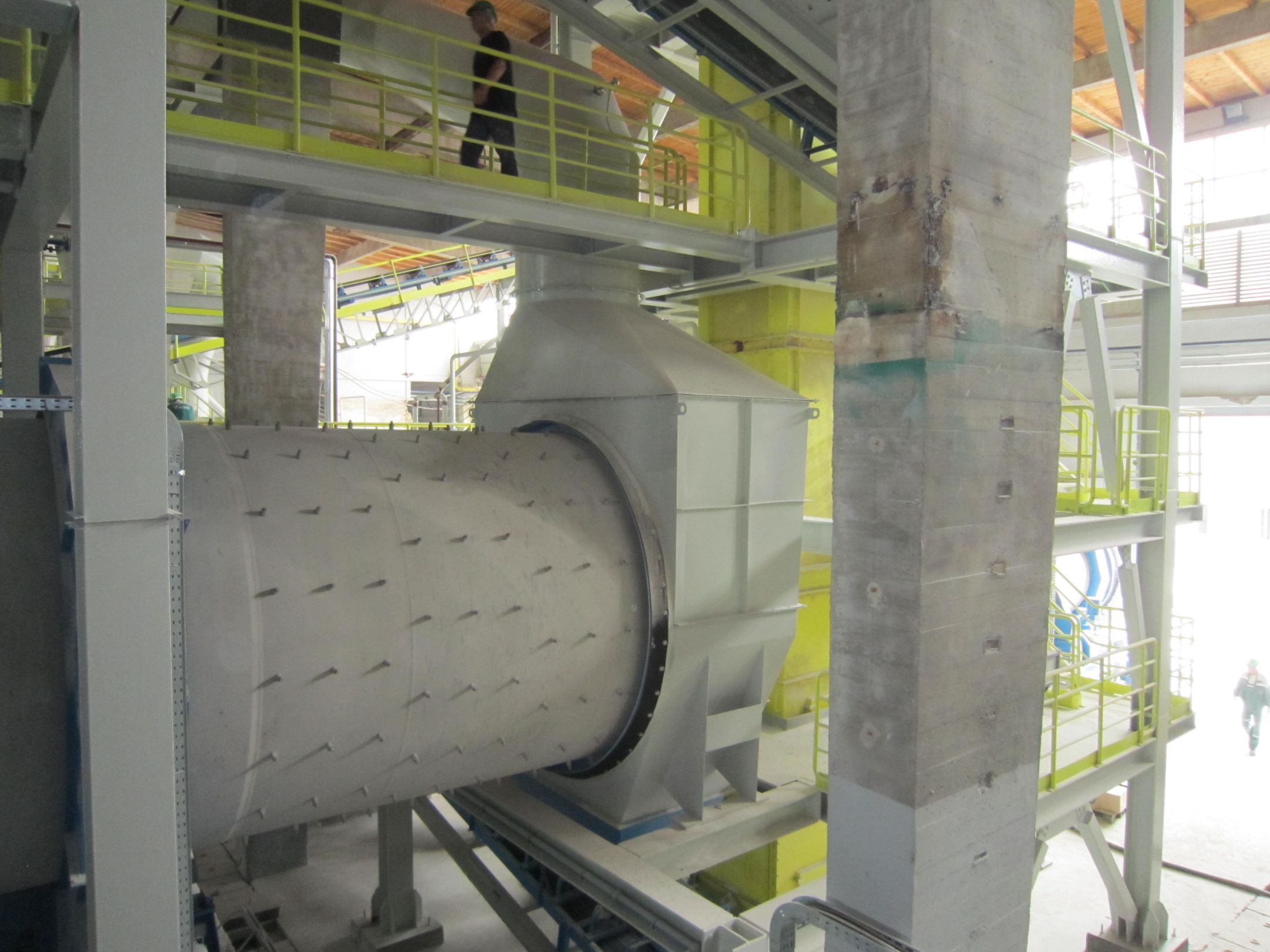

FLUIDIZED ROTARY GRANULATOR

Fluidized rotary granulator is a very specific type of equipment where a static fluidized table is installed inside the rotating granulator.

The particles are spread with solution or melt and are further lifted and falling onto the fluidized table. Hot air ensures the fluidization at the surface of the table.

Products by fluidized rotary granulator

References:

GRANULATOR-DRYER

The granulator-dryer is a 2-in-1 drum used in very specific applications.

In the first part, the solution is sprayed via headers onto the particles bed and granulation occurs. In the second part, hot air is blown, crossing the flow of granules, and the drying occurs.